«АСВ-СТП» (Станки. Технология. Производство)

Станки и оборудование для металло- и деревоообработки. Новые и б/у

Brief Description of Model SZ-125EI :

Model SZ-125EI Technical Parameters

| Item | SZ-125EI |

| Control system | FANUC |

| Max Machining bar dia. | Φ12mm |

| Max machining length | 205mm |

| Front drilling dia. | Max Φ8mm |

| Front thread (Tap / die) machining | Max M6 |

| Main spindle though-hole dia. | Φ13mm |

| Main spindle speed | Max 10000r/min |

| Drilling dia of profile rotary tool | Max Φ7mm |

| Tapping dia of profile rotary tool | Max M6 |

| Servo motor speed of profile rotary tool | Max 5000r/min |

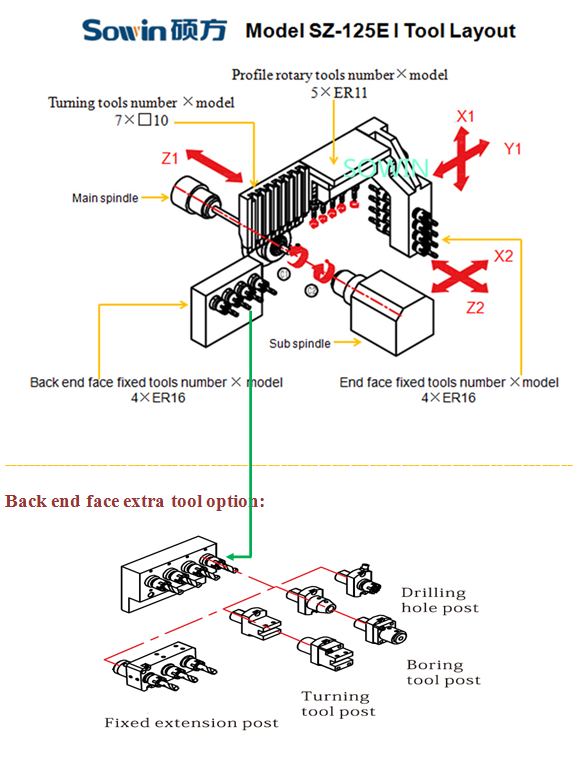

| Turning tools number × model | 7×□10 |

| Profile rotary tools number × model | 5×ER11 |

| End face fixed tools number × model | 4×ER16 |

| Back end face fixed tools number × model | 4×ER16 |

| Rapid feed | 30m/min(Z1/Z2/X2/Y) 24m/min(X1) |

| Main spindle motor power | 1.5/2.2Kw |

| Sub spindle motor power | 1.5/2.2Kw |

| Rotary servo motor power | 0.75Kw(Profile milling) |

| Feed drive servo power | 0.75Kw(Z1/Z2/X1/X2/Y) |

| Max chuck dia of sub spindle | Φ12mm |

| Max protrusion length of sub spindle | 30mm |

| Max drilling dia in sub spindle machining process | Max Φ8mm |

| Max thread (tap) dia in sub spindle machining process | Max M6mm |

| Sub spindle speed | Max 10000r/min |

| Back end face fixed tool drilling dia | Max Φ6mm |

| Back end face fixed tool tapping | Max M6mm |

| Cutting Oil pump power | 0.4Kw |

| Spindle temp. control oil pump power | 0.1Kw |

| Lubricating oil pump power | 0.015Kw |

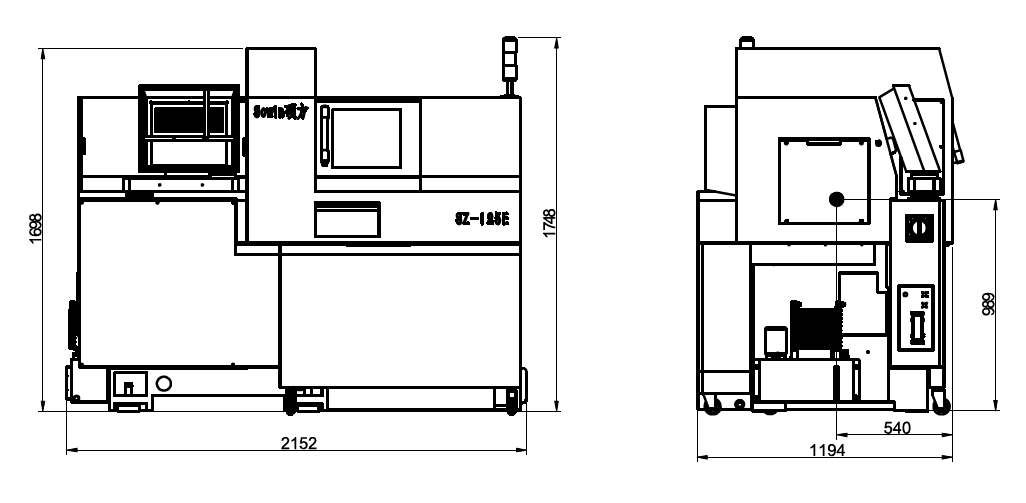

| Center height | 989mm |

| Net Weight | 2500KG |

| Dimensions(L×W×H) | 2152mm×1194mm×1748mm |

| Standard Configuration | Optional Configuration |

| Main / (Sub) spindle | Long work piece recovery device |

| Temperature control system | Cut-off tool breakage detector |

| Working light (LED light) | Chip conveyor |

| 3-color signal tower | High pressure cooling device |

| Rotary guide bushing | Oil mist collector |

| Parts catcher | Special shape material clamping device |

| External lighting lamp interface | Long arm light |

| 10.4-inch color LCD display | Special VDI rotary tool post |

| Chucking sleeve(Main/Sub) | Material cut-off detector |

| Synchronous rotary guide bushing | Automatic extinguisher |

| Chucking device (Main/Sub) | Automatic bar feeder |

| Door switch |

|

| Separate cutting oil tank |

|

| Product ejector |

|

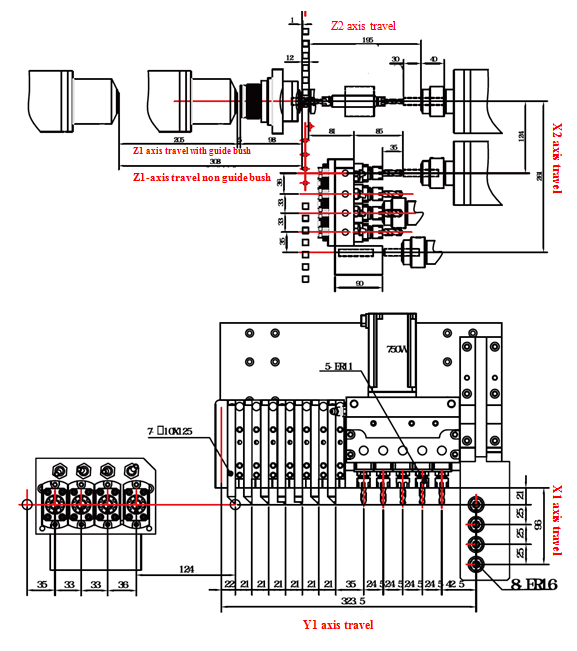

Route Interferogram