«АСВ-СТП» (Станки. Технология. Производство)

Станки и оборудование для металло- и деревоообработки. Новые и б/у

Technical Parameters

|

Item |

SC-46YL2 |

|

|

Control system |

FANUC |

|

|

Main spindle |

Spindle front-end type |

ANSI A2-5 |

|

Distance from spindle center to work table |

75mm |

|

|

Dynamic system |

Main spindle servo motor power |

5.5Kw(SYNTE)/4.4Kw(YASKAWA) |

|

X-axis servo motor power |

1.8Kw(YASKAWA) |

|

|

Y-axis servo motor power |

0.75Kw(YASKAWA) |

|

|

Z-axis servo motor power |

1.3Kw(YASKAWA) |

|

|

Rotary head servo motor power |

1.0Kw(YASKAWA) 1.5Kw(YASKAWA) |

|

|

Machining range |

Set main spindle max speed |

4500r/min |

|

Main spindle max swing dia. |

Φ400mm |

|

|

Max material bar though dia. |

Φ45mm |

|

|

X-axis max travel |

700mm |

|

|

Y-axis max travel |

210mm |

|

|

Z-axis max travel |

350mm |

|

|

X/Z rapid travel speed |

20m/min |

|

|

Y rapid travel speed |

24m/min |

|

|

Machining precision |

X/Y/Z repeat positioning accuracy |

0.003mm |

|

X/Y/Z positioning accuracy |

±0.005mm |

|

|

Spindle rotation jumpiness |

0.003mm |

|

|

Tool configuration |

Live head tool × Model |

7×ER20A |

|

Hydraulic or servo turret |

Turning tool 20×20 Boring tool Φ25 (Φ20) |

|

|

Net weight |

3500KG |

|

|

Dimensions |

(L×W×H) |

2410×1960×2140mm |

The key components and internal devices

1. High precision, high rigidity, all in one lathe base structure

a) 45℃slanted one-piece cast iron construction with internal heavy duty ribbing reduces vibrations and ensure the rigidity. Stress relived to remain de-formation-free year-after-year.

b) The bed structure is designed to suit coolant flow direction, which minimizes the possibility of coolant leakage while allowing smooth chip exhaust.

c) Compact design, able to install in a narrow space

2. High speed guide way HIWIN or PMI brand

HIWIN or PMI guide is adapted on each guide section with 30 m/min of rapid feed speed. Especially, maintaining non-changeable precision for sustained use by adopted a PMI or HIWIN guide on the surface, which can minimize malfunction and wear that occurs in general slides.

HIWIN or PMI guide is adapted on each guide section with 30 m/min of rapid feed speed. Especially, maintaining non-changeable precision for sustained use by adopted a PMI or HIWIN guide on the surface, which can minimize malfunction and wear that occurs in general slides.

3. PMI ball screw

Ball screw is fixed at its end by double anchor type, which makes it in parallel with guide way and achieves a stable forwarding. Especially, a ball screw with larger diameter is adopted and pre-pressure is applied, which improve thermal deformation and hardness.

Ball screw is fixed at its end by double anchor type, which makes it in parallel with guide way and achieves a stable forwarding. Especially, a ball screw with larger diameter is adopted and pre-pressure is applied, which improve thermal deformation and hardness.

4. POSA high precision and high rigidity main/sub Spindle

Spindle is designed to maintain high speed, high precision, high rigidity for a long continues operation by basically shutting off the heat with base and anti-heat plats.

Spindle is designed to maintain high speed, high precision, high rigidity for a long continues operation by basically shutting off the heat with base and anti-heat plats.

5. Japan FANUC control system

5. Japan FANUC control system

1. FANUC 0i-TF system, high stability

2. Various G/M codes, suitable for basic mill/lathe

3. HPCC optimizes tool path and achieve finger surface

4. 3+1 axes CNC controller, 2 USB ports, 1 AN port

5. G-code programming, PLC ladder programming

6.USB connector—easer file transfer and support keyboard

7. Fluent HMI switching & instant boot up/I/O, 2 analogue outputs

6. Servo motor & drivers

Japan FANUC drivers---more smart. |

1.

Japan YASKAWA feed servo motor;

2. FANUC main spindle servo motor;

|

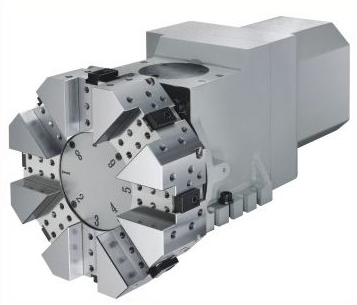

7. High quality oil bar feeder |

Taiwan “JIAHE 6” Chuck, Range:φ15mm~φ168mm |

| 8. 1) Taiwan “JIAHE 6” Hydraulic or Servo turret Low failure rate and quick tool change, Mini change time 0.1second/step; ompact structure, high precision, high repositioning;  |

2) Live Head / Rotating tool |

9. Taiwan HERG Guide rail lubricating system |

10. Hydraulic system Space-saving; Low noise,

Good

oil way design;

Easy

maintenance Low noise,

Good

oil way design;

Easy

maintenance

|

Copyright reserved by SOWIN.